Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

モデル: GB/T14976

ブランド: Torich

包装: 木箱または六角形の束での梱包

生産高: 20000 Tons per Year

輸送方法: Ocean,Land,Air

原産地: 浙江、中国(本土)

についてのサポート: 60000 Ton per year

認証 : ISO9001:2008 ISO14001:2008, TS16949, CE PED, TUV, API

HSコード: 7306301100

ポート: Shanghai,Ningbo

お支払い方法の種類: L/C,T/T,D/P,Paypal,Money Gram,Western Union

インコタームズ: FOB,CFR,CIF,FCA,CPT

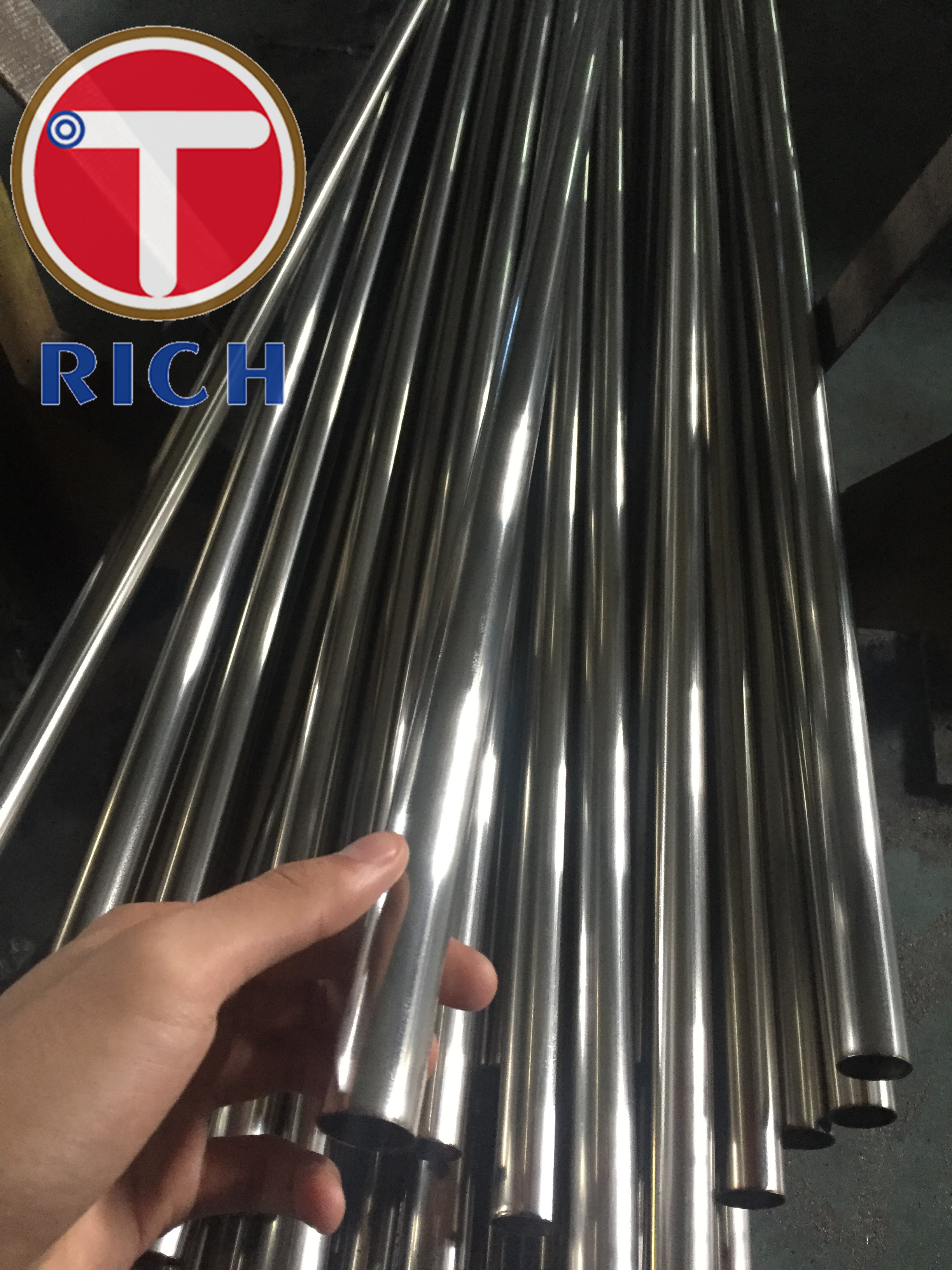

中国ステンレス鋼管メーカー、私たちのステンレス鋼の排気管、溶接鋼管、丸いステンレス鋼管、ポーランドのステンレス鋼管、ステンレスコイル管、二重ステンレス鋼管は、品質と価格競争力が良いです。

製品名 :TORICH GB / T14976 ASTM A269 A312シームレス鋼管

標準 : GB / T14976 ASTM A269 A312

OD:3-420mm

WT:0.5〜50mm

長さ :1-12メートルまたは 顧客の実際のアプリケーションと生産に応じて。

アプリケーション : フルイード輸送用

スチールグレード :201/202/304 / 304L / 316 / 316L321 / 310/410/420/430/440 / 439ect

テクノロジー :冷間圧延冷間圧延

特性:

良好な同心性

良好な表面品質

良好なODおよびID許容値

高精度

安定した品質

滑らかな粗さ

トーリーク・アシュアランス

表1外径と肉厚の許容差単位 : mm

|

Hot rolling(extrusion,expansion) steel tube |

Cold drawn(rolling)steel tube |

||||||

|

Diamension |

Tolerance |

Diamension |

Tolerance |

||||

|

Ordinary Grade PA |

High Grade PC |

Ordinary Grade PA |

High Grade PC |

||||

|

Nominal Outer Diameter D |

68~159 |

±1.25%D |

±1%D |

Nominal Outer Diameter D |

6~10 |

±0.20 |

±0.15 |

|

>10~30 |

±0.30 |

±0.20 |

|||||

|

>30~50 |

±0.40 |

±0.30 |

|||||

|

>50~219 |

±0.85%D |

±0.75%D |

|||||

|

>159 |

±1.5%D |

>219 |

±0.9%D |

±0.8%D |

|||

|

Nominal Wall Thickness S |

<15 |

+15%S -12.5%S |

±12.5%S |

Nominal Wall Thickness S |

≤3 |

±12%S |

±10%S |

|

≥15 |

+20%S -15%S |

>3 |

+12.5%S -10%S |

±10%S |

|||

表2最小肉厚の許容差単位:mm

|

Manufacturing Method |

Diamension |

Tolerance |

|

|

Ordinary Grade PA |

High Grade PC |

||

|

Hot rolling(extrusion,expansion) steel tube W-H |

Smin<15 |

+25%Smin 0 |

+22.5%Smin 0 |

|

Smin≥15 |

+32.5%Smin 0 |

||

|

Cold drawn(rolling)steel tube W-C |

All Wall Tickness |

+22%Smin 0 |

+20%Smin 0 |

表3グレードおよび化学成分

|

No. |

GB/T 20878 |

Grade |

|

Chemical Component(Quality Fraction)/% |

||||||||||

|

No. |

Unified Digital Code |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

N |

Others |

||

|

13 |

S30210 |

12Cr18Ni9 |

0.15 |

1.00 |

2.00 |

0.035 |

0.030 |

8.00~10.00 |

17.00~19.00 |

- |

- |

0.10 |

- |

|

|

2 |

17 |

S30408 |

06Cr19Ni10 |

0.08 |

1.00 |

2.00 |

0.035 |

0.030 |

8.00~11.00 |

18.00~20.00 |

- |

- |

- |

- |

|

3 |

18 |

S30403 |

022Cr19Ni10 |

0.030 |

1.00 |

2.00 |

0.035 |

0.030 |

8.00~12.00 |

18.00~20.00 |

- |

- |

- |

- |

|

4 |

23 |

S30458 |

06Cr19Ni10N |

0.08 |

1.00 |

2.00 |

0.035 |

0.030 |

8.00~11.00 |

18.00~20.00 |

- |

- |

0.10~0.16 |

- |

|

5 |

24 |

S30478 |

06Cr19Ni9NbN |

0.030 |

1.00 |

2.50 |

0.035 |

0.030 |

7.50~10.50 |

18.00~20.00 |

- |

- |

0.15~0.30 |

Nb:0.15 |

|

6 |

25 |

S30453 |

022Cr19Ni10N |

0.08 |

1.00 |

2.00 |

0.035 |

0.030 |

8.00~11.00 |

18.00~20.00 |

- |

- |

0.10~0.16 |

- |

|

7 |

32 |

S30908 |

06Cr23Ni13 |

0.030 |

1.00 |

2.00 |

0.035 |

0.030 |

12.00~15.00 |

22.00~24.00 |

- |

- |

- |

- |

|

8 |

35 |

S31008 |

06Cr25Ni20 |

0.08 |

1.50 |

2.00 |

0.035 |

0.030 |

19.00~22.00 |

24.0~26.00 |

- |

- |

- |

- |

|

9 |

38 |

S31608 |

06Cr17Ni12Mo2 |

0.08 |

1.00 |

2.00 |

0.035 |

0.030 |

10.00~14.00 |

16.00~18.00 |

2.00~3.00 |

- |

- |

- |

|

10 |

39 |

S31603 |

022Cr17Ni12Mo2 |

0.030 |

1.00 |

2.00 |

0.035 |

0.030 |

10.00~14.00 |

16.00~18.00 |

2.00~3.00 |

- |

- |

- |

|

11 |

40 |

S31609 |

07Cr17Ni12Mo2 |

0.04~0.10 |

1.00 |

2.00 |

0.035 |

0.030 |

10.00~14.00 |

16.00~18.00 |

2.00~3.00 |

- |

- |

- |

|

12 |

41 |

S31668 |

06Cr17Ni12Mo2Ti |

0.08 |

1.00 |

2.00 |

0.035 |

0.030 |

10.00~14.00 |

16.00~18.00 |

2.00~3.00 |

- |

- |

Ti:5C~0.70 |

表4推奨される熱処理システム。ステンレス鋼管の機械的性質と密度

|

Organization type |

No. |

GB/T 20878 |

Grade |

Recommended Heat Treatment System |

Mechanical Properties |

Density ρ/(kg/dm2) |

|||

|

No. |

Unified digital code |

Tensile strength Rm/MPa |

Specified plastic elongation strength Rp0.2/MPa |

Percentage elongation after fracture A/% |

|||||

|

Not less than |

|||||||||

|

Austenitic |

1 |

13 |

S30210 |

12Cr18Ni9 |

1010℃~1150℃,cold or otherwise |

520 |

205 |

35 |

7.93 |

|

2 |

17 |

S30408 |

06Cr19Ni10 |

1010℃~1150℃,cold or otherwise |

520 |

205 |

35 |

7.93 |

|

|

3 |

18 |

S30403 |

022Cr19Ni10 |

1010℃~1150℃,cold or otherwise |

480 |

175 |

35 |

7.90 |

|

|

4 |

23 |

S30458 |

06Cr19Ni10N |

1010℃~1150℃,cold or otherwise |

550 |

275 |

35 |

7.93 |

|

|

5 |

24 |

S30478 |

06Cr19Ni9NbN |

1010℃~1150℃,cold or otherwise |

685 |

345 |

35 |

7.98 |

|

|

6 |

25 |

S30453 |

022Cr19Ni10N |

1010℃~1150℃,cold or otherwise |

550 |

245 |

40 |

7.93 |

|

|

7 |

32 |

S30908 |

06Cr23Ni13 |

1010℃~1150℃,cold or otherwise |

520 |

205 |

40 |

7.98 |

|

|

8 |

35 |

S31008 |

06Cr25Ni20 |

1010℃~1150℃,cold or otherwise |

520 |

205 |

40 |

7.98 |

|

|

9 |

38 |

S31608 |

06Cr17Ni12Mo2 |

1010℃~1150℃,cold or otherwise |

520 |

205 |

35 |

8.00 |

|

|

10 |

39 |

S31603 |

022Cr17Ni12Mo2 |

480 |

175 |

35 |

8.00 |

||

|

11 |

40 |

S31609 |

07Cr17Ni12Mo2 |

≥1040℃,cold or otherwise |

515 |

205 |

35 |

7.98 |

|

|

12 |

41 |

S31668 |

06Cr17Ni12Mo2Ti |

1000℃~1100℃,cold or otherwise |

530 |

205 |

35 |

7.90 |

|

表5鋼管検査項目。試験方法とサンプリング数

|

No. |

Inspection Item |

Sampling Quantity |

Sampling Method |

Test Method |

|

1 |

Chemical Component |

Take a sample of each furance |

GB/T 20066 |

GB/T 223.GB/T 11170.GB/T20123.GB/T 20124 |

|

2 |

Tensile Test |

Take a sample between two steel tubes of each batch |

GB/T 2975 |

GB/T 228.1 |

|

3 |

Flattening Test |

Take a sample between two steel tubes of each batch |

GB/T 246 |

GB/T 246 |

|

4 |

Flaring Test |

Take a sample between two steel tubes of each batch |

GB/T 242 |

GB/T 242 |

|

5 |

Hydraulic Test |

Each piece |

- |

GB/T 241 |

|

6 |

Ultrasonic Test |

Each piece |

- |

GB/T 5777-2008 |

|

7 |

Eddy Test |

Each piece |

- |

GB/T 7735-2004 |

|

8 |

Intercrystalline corrosion test |

Take a sample between two steel tubes of each batch |

GB/T 4334-2008 |

GB/T 4334-2008 |

製品グループ : ステンレス鋼管

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.